Tel: 86-577-66601672

Fax: 86-577-65907012

Mobile: 0086-13282718181

Skype: jackyliu222

E-mail: sales1@clmachinery.com

Address: No.168 Xiachang Industrial Area, Feiyun Town, Ruian City, Zhejiang, China

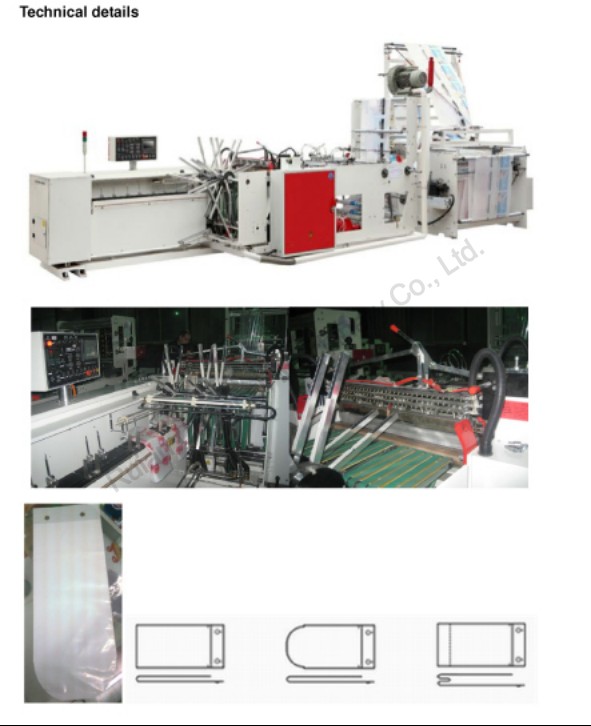

It is used to make plastic wicket bags, bread bags, round bottom chicken bags etc.

It is used to make plastic wicket bags, bread bags, round bottom chicken bags etc.

Main features:

1). Suitable side sealing HDPE/LDPE/BOPP

2). Kinds of bags: Wicket bag, chicken bag and bread bag

3). The whole machine is controlled by Panasonic, Japan PLC.

4). The machine adopts multi-colored touch human-computer interface real time display from Taiwan.

5). Feeding material device adopts Yaskawa brand servo motor.

6). Main motor is 1.5kw inverter motor with brake and 1.5kw Yaskawa inverter control

7). The machine adopts digital display temperature controllers.

8). With bottom gusset device

9). Automatic collect waste films

10). Equipped with EPC control system on the unwinder station.

11). The Unwinding stations adopts air shafts and constant tension control, and the feeding speed is in according with the production speed.

12). The unwinding station adopts V-folding device to fold the plastic film sheet.

13). Equipped with two pneumatic hole punchers, the standard hole diameter is 14mm.

14). Equipped with auto pneumatic round bottom chicken puncher

15). New design fast side sealing knife

16). With high qaulity sealing knife

17). Automatic windmill style rotary-arm to collect the finished bags, its speed changes according to the main motor speed.

18). 2kw Yaskawa Servo motor for take up of collecting the bags.

19). With Sick brand, Germany photocell to track the color

20). With pre-chopped device for the bags.

Main technical parameters:

Unwinder roll film width: 800mm (Bag length is 750mm+50mm(Pre-chopped film width)=800mm))

Width of bag making: 100-350mm

Bottom gusset width: 30-70mm

Speed of machin: max.250pcs/min

Total power: 22kw

Weight: 2200kg

Dimension: 8000mm*2800mm*1950mm

Brands of electrical parts:

1). Cylinder: SHANKO, TAIWAN

2). Photocell: Sick, Germany

3). Feeding servo motor: 4.4kw Yaskawa, Japan

4). Sevo motor of collecting bags table: 3kw Yaskawa, Japan

5). Main motor: 1.5kw with brake, Taiwan

6). Back feeding motor: 750W, China

7). EPC system of unwinding and folding and 2pcs hole puncher: China

8). Inverter: 1.5kw,0.75KW*2pcs, Yaskawa, Japan

9). PLC control drive: Panasonic, Japan

10). Touch screen: Weinview, Taiwan

11). Potentiometer: Shanghai, China

12). Proximity switch: Shanghai, China

13). Air switch: China

14). AC contactor: China

15). Switch button and knob: Schneider, France

16). Power switch: Taiwan

17). Bearing: SKF

| * Subject: | ||

| * Message: | ||

| * Contact: | ||

| * Email: | ||

| (Enter the correct contact information, to ensure that we can contact you.) | ||

| CompanyName: | ||

| * Phone: | ||

| (Enter the correct contact information, to ensure that we can contact you.) | ||

| Fax: | ||

| Address: | ||