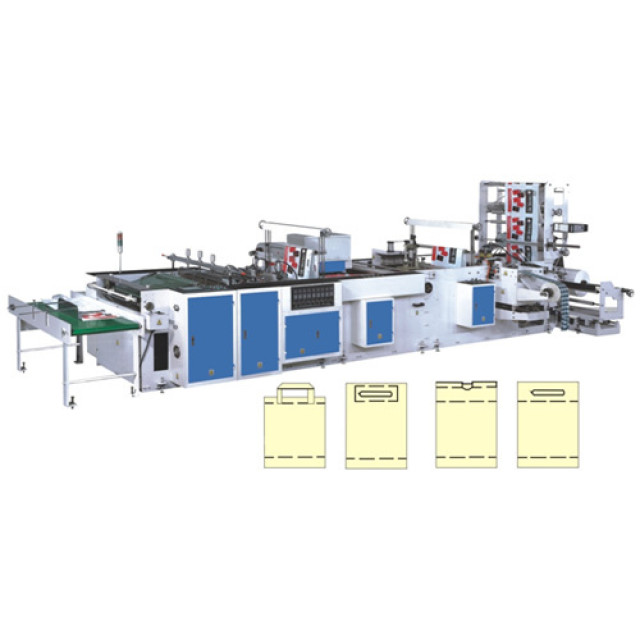

This machine is specially designed to produce plastic patch handle bags/soft loop handle bags/string bags

Features:

- Overall computercontrol

- Equipped with EPC device(Web guiding device) and magnetic powder tension controller on the unwinder station.

- Equipped with cutting knife to cut the tubular film open at one side of the film.

- With device to put plastic attachment to the bags and punch the handle holes on the bag automatically.

- Panasonic brand, Japan Inverters to control the main motor and save the electricity.

- Equipped with one photocell to track the color

- With auto delivery belt conveyor to collect the bags.

- 9. Anti-static bar,auto alarm and auto counting meter.

- Equipped with the Panasonic brand, Japan servo motor.

- Equipped with auto pneumatic hole puncher

- Auto add glue slip on the bag

Main technical parameters:

Types of bags making : patch handle bags

Width of unwinding material:800mm

Diameter of roll material:Max. ¢600mm

Length of bag-making:250-750mm

Width of bag-making:250-600mm

Folding width: 30-70mm

Thickness of film:0.03-0.08mm

Length of soft loop: 360mm

Thickness of bag:HDPE 0.11-0.18mm(Double)

Speed of making bag: 60pcs/min

Total power: 6KW

Dimension:4600X2200X1850mm

Weight:2200kg

Air compressor:6HP